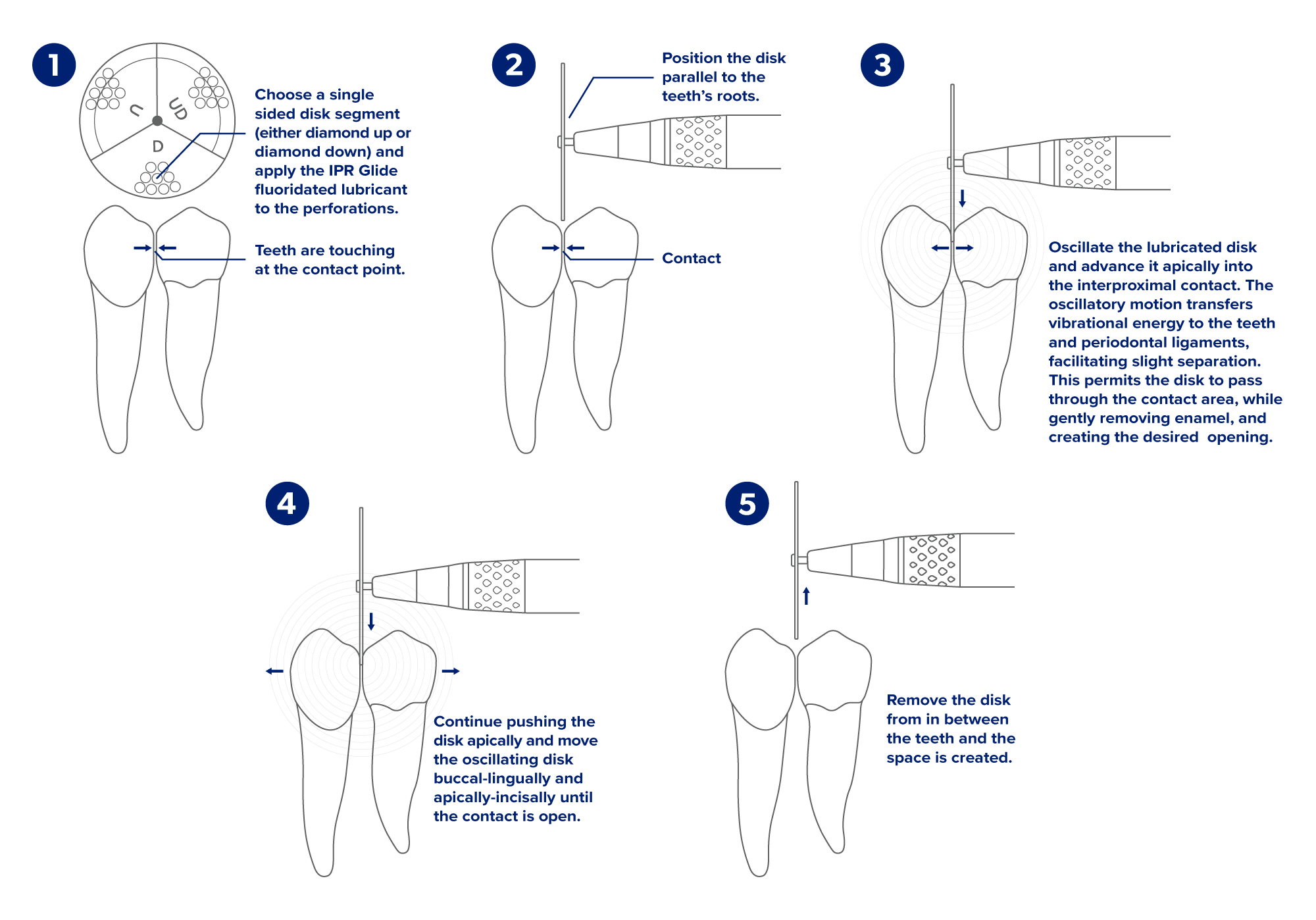

The smartIPR system delivers safe, precise space creation by polishing enamel surfaces—never cutting hard or soft tissue.

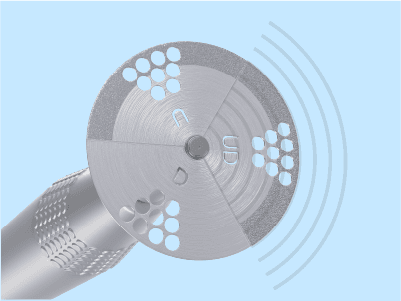

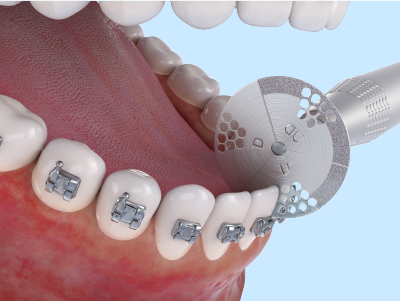

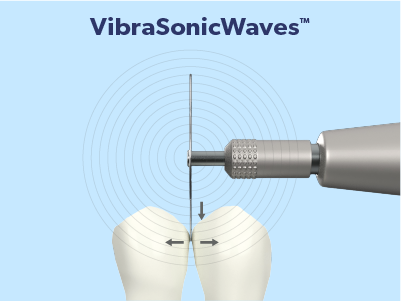

smartIPR integrates novel instrument design with oscillation, vibration, and lubrication to deliver a breakthrough in IPR.

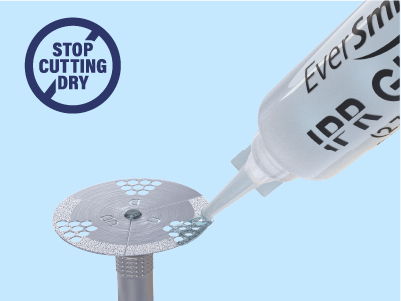

IPR Glide lubricates IPR instruments to enhance the procedure while delivering Rx fluoride to abraded enamel surfaces. It is compatible with all IPR strips and disks.

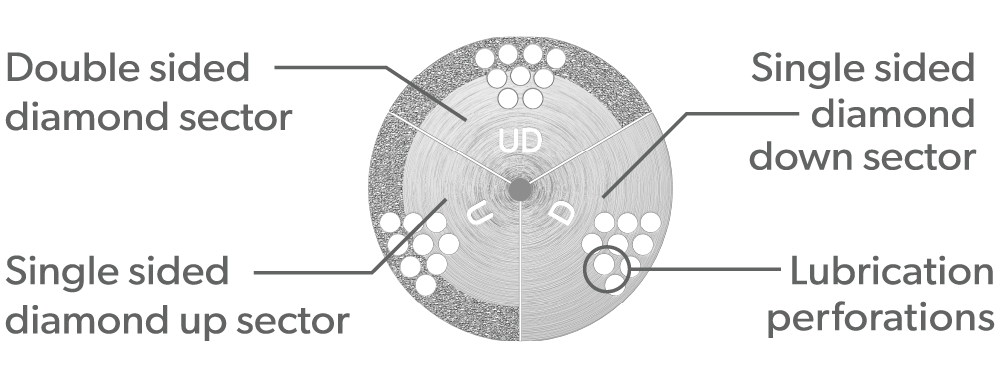

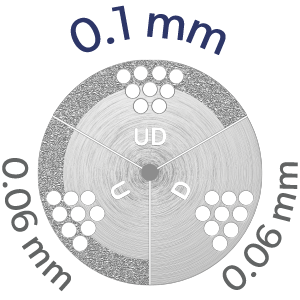

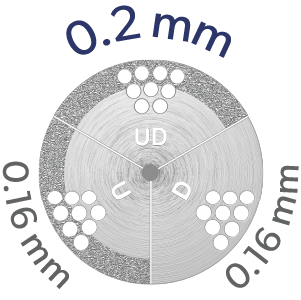

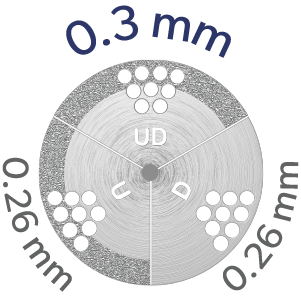

Oscillating, lubricated smartDISKS gently vibrate in between teeth polishing enamel surfaces, creating space.